ZNQ Submersible mud pump

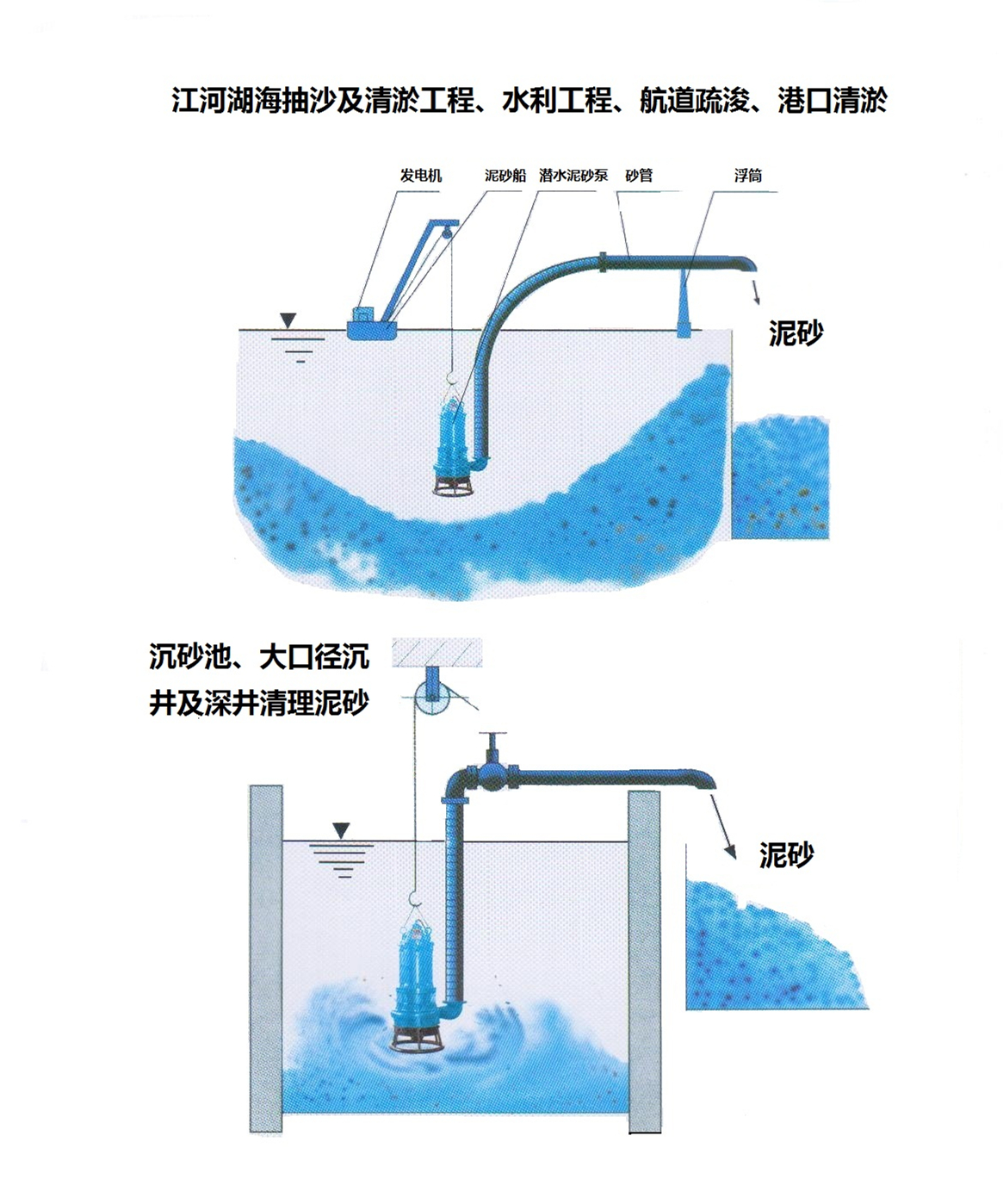

Brief introduction: ZNQ submersible mud pump is a hydraulic machine that works coaxially with the motor and the pump to submerge into the medium. The pump has high efficiency, strong abrasion resistance, built-in stirring, complete model, and has some innovations in hydraulic and structural design. Anti-abrasion high chromium wear-resistant alloy casting is an ideal equipment for pumping mud, dredging, sand suction and slag discharge. Can be widely used in chemical, mining, thermal power, metallurgy, pharmaceutical, bridge and pile foundation engineering, coal, environmental protection and other industries to transport slurry containing abrasive solid particles. Such as iron and steel plants pumping iron oxide scales, factory sedimentation pond sediment cleaning, gold ore sand washing, ore slurry ore conveying, metallurgical ore conveying plant ore conveying, hydraulic ash removal in thermal power plants, coal slurry and heavy media conveyance in coal washing plants, dredging of river channels, River dredging and dredging, pile foundation engineering, etc.

Model meaning:

100 ZNQ (R)(X)100-28-15(L)

100 – Nominal diameter of pump discharge port(mm)

ZNQ – submersible mud pump

(R) –High temperature resistant

(X) –Stainless steel

100 – rated flow rate (m3/h)

28 –rated head (m)

15 –motor rated power (Kw)

L) –cooling cover

Technical data

According to diameter ,there is 2、3、4,6,8,10,12,14 inch ,power :3KW-132KW,we can also produce according to customer requirement

Working principle

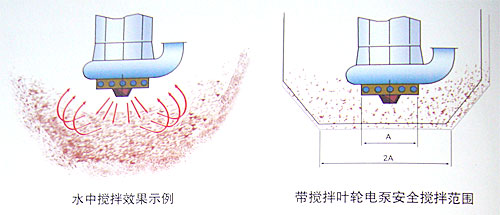

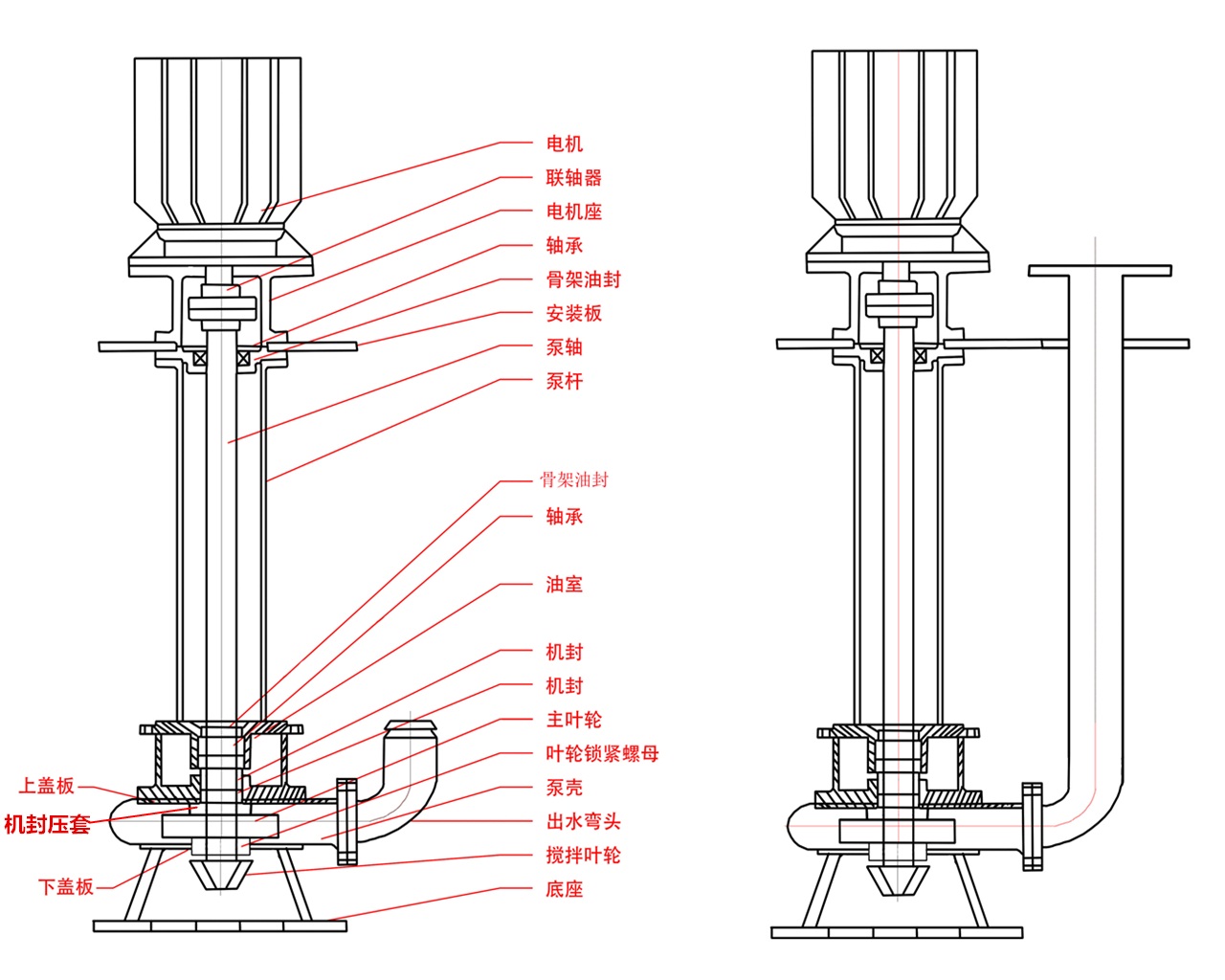

In addition to the main impeller, the bottom is also equipped with a stirring impeller. The motor shaft drives the water pump impeller and the stirring impeller to rotate at a high speed to transfer energy to the slurry medium, so that the sediment, sediment, and slurry are stirred evenly, and the pump is not in In the case of an auxiliary device, high-concentration conveyance is achieved.

In addition, for special conditions where the sediment is compacted or the sand layer is hard, and it cannot be completed only by the pump impeller and self-priming, two-sided and multilateral agitators (reamers) can be added to loosen the sediment and increase the extraction concentration. To achieve automatic hinge suction. It also prevents bulky solids from clogging the pump, allowing solids and liquids to be fully mixed for easier handling.

Pump over-flow material: normal configuration high chromium wear-resistant alloy(cr26)。

Others such as ordinary wear-resistant alloys, ordinary cast iron, cast steel, 304, 316, and 316L stainless steel, and duplex stainless steel can be customized according to different working conditions and customer requirements.

Products characters:

1.It is mainly composed by motor, pump casing, impeller, guard plate, pump shaft and bearing seals, etc.

2.The pump casing, impeller, and guard plate are made of high-chromium alloy wear-resistant materials, which are resistant to abrasion, corrosion, and sand, and can pass large solid particles.

3.The whole machine is a dry pump type. The motor adopts an oil chamber sealing method. There are three sets of hard alloy mechanical seals inside, which can effectively prevent high pressure water and impurities from entering the inner cavity of the motor.

4.In addition to the main impeller, there is also a stirring impeller, which can stir the sediment deposited on the bottom of the water into a turbulent flow and extract it.

5.The stirring impeller directly contacts the deposition surface, and the concentration is controlled by the diving depth. In addition, due to the large precipitation hardness and compaction of the medium, an auxiliary reamer can be added to increase the concentration of medium extraction.

6. Not limited by suction range, high slag suction efficiency, more dredging

7. The equipment works directly under water without noise and vibration, and the site is cleaner.

Working conditions:

1. Normally 380v / 50hz, three-phase AC power. It can also order 50hz or 60hz / 230v, 415v, 660v, 1140V three-phase AC power supply. The capacity of the distribution transformer is 2-3 times the rated capacity of the motor. (Specify the power supply conditions when ordering)

2. The working position in the medium is vertical upper suspension positioning, and can also be coupled and installed, and the working state is continuous.

3. Crew diving depth: no more than 50 meters, the minimum diving depth is based on the submerged motor.

4. The maximum concentration of solid particles in the medium: 45% for ash and 60% for slag.

5. The medium temperature must not exceed 60 ℃, and the R type (high temperature resistance) does not exceed 140 ℃, and it does not contain flammable and explosive gases.

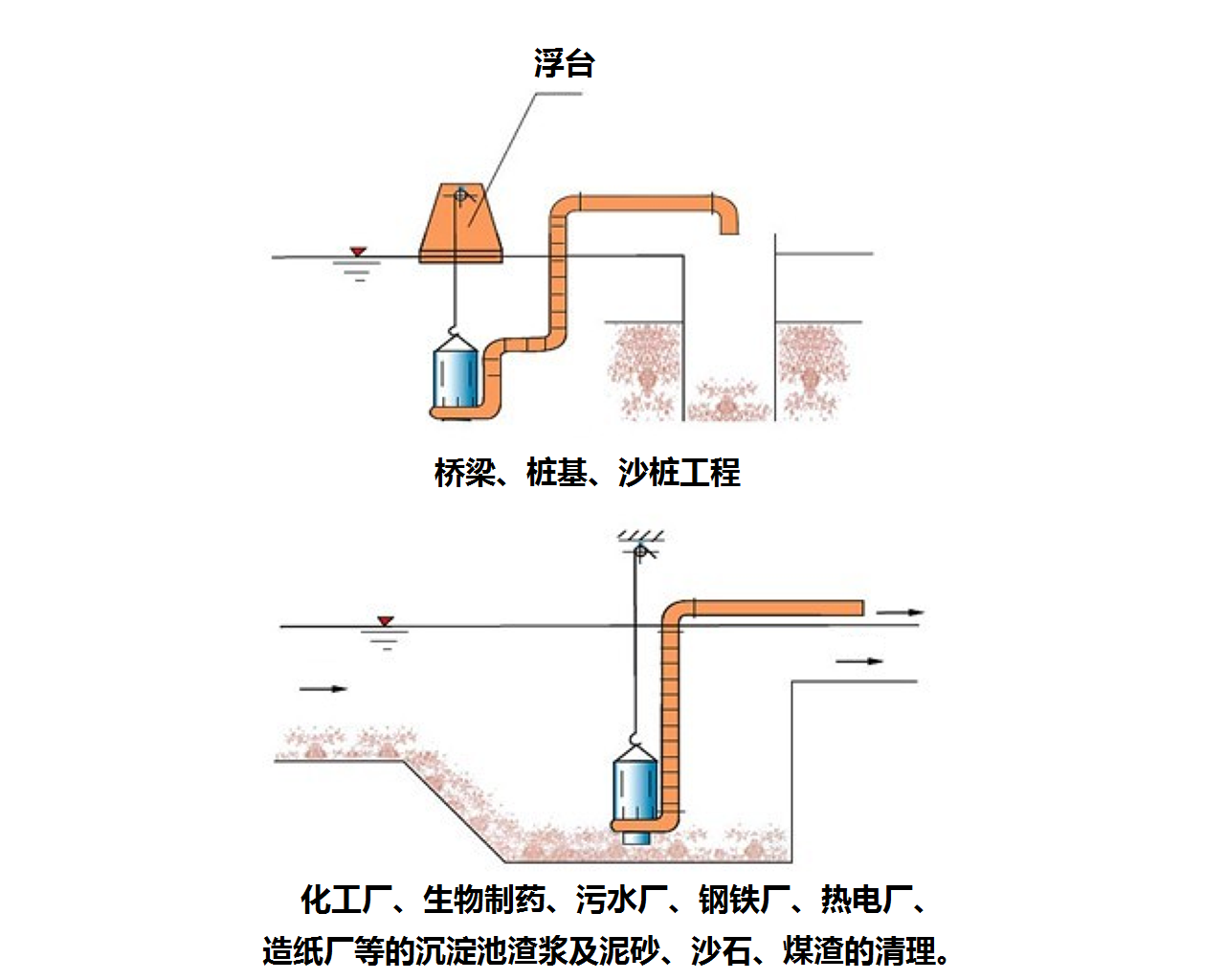

Scope of application: (not limited to the following)

1. Chemical industry, biology, thermal power, smelting, ceramics, pharmaceuticals, textiles and other industries sedimentation tank sediment extraction and transportation.

2. Sewage treatment plant, iron and steel plant, thermal power plant, paper mill and other sedimentation tank sludge and sediment, sand and gravel removal.

3. Coal washing slurry, coal slag, power plant fly ash slurry, coal slime extraction, transportation.

4. Cleaning of tailings pond, transportation of sand, slag and ore slurry in the mineral processing plant.

5. Desilting of large-diameter deep wells, sand piles, municipal pipelines and bridge pier construction.

6. High temperature waste slag, boiler high temperature slurry, heat-resistant scale, metallurgy and other high temperature slag discharge.

7. Diamond powder, tailings ore, quartz sand ore, rare earth ore, etc. are used to extract ore powder and mortar.

8. Coastal reclamation, sand unloading and reclamation, power station water storage and sediment regulation, etc.

9. Transportation and removal of various slurry materials such as ceramics and marble powder.

10. Sediment and sludge treatment for construction and water conservancy projects, industrial and mining enterprises, and municipal engineering.

11. Sediment drainage, silt, pile hole construction of sinking wells, and drainage drainage during bridge pier construction.

12. Sediment removal from municipal pipelines, rainwater pumping stations, and hydropower stations.

13. Desilting and sand absorption projects for rivers, lakes, reservoirs, and urban rivers.

14. Deep-water dredging projects such as ports, wharves, and navigation channels, and sediment management.

15. Convey other slurry-like media containing larger solid particle

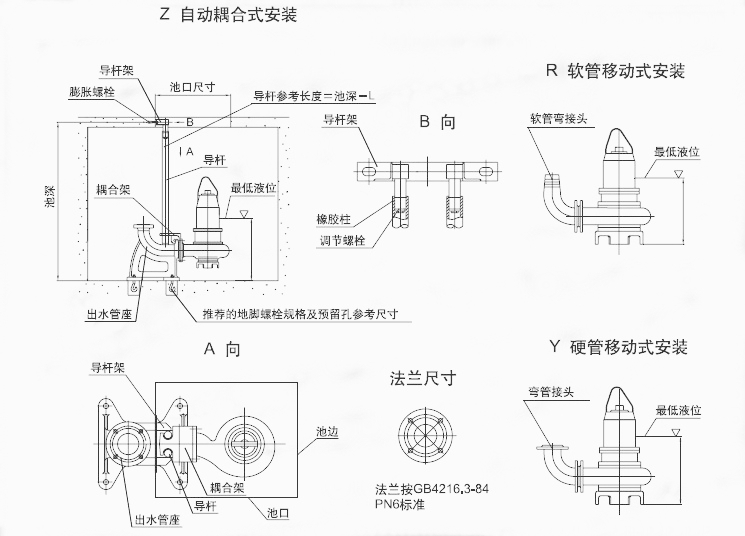

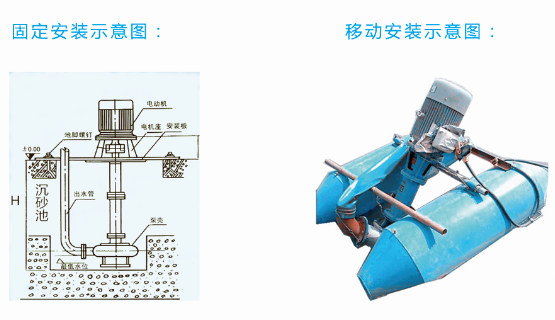

Installation method

The submersible sand pump produced by our company has a coaxial pump, compact structure, high efficiency, convenient installation and maintenance, economic operation, and strong adaptability. Its installation methods include mobile installation and fixed installation. Fixed installation is divided into automatic Coupling installation and fixed dry installation, mobile installation is also called free installation.

Mobile installation method The electric pump is supported by a bracket, and the water outlet hose can be connected. Suitable for river treatment, industrial sewage discharge, pumping of municipal construction sludge and other occasions.

Automatic coupling installation

The automatic coupling installation device can quickly and easily put the electric pump into the sand medium along the sliding guide rail, and the pump and the base are automatically coupled and sealed. Installation and maintenance are very convenient.

In this type of installation, the pump is connected to the coupling device, and the coupling base is fixed to the bottom of the pump pit (when the sewage pit is built, the anchor bolts are embedded and the coupling base can be fixed when in use). It moves up and down automatically. When the pump is lowered, the coupling device is automatically coupled with the coupling base, and when the pump is lifted, it is automatically disconnected from the coupling base.

This way can be equipped with hydraulic switches, intermediate terminal boxes and fully automatic protection control cabinets according to user requirements. In the selection, the pump model, installation method, tank depth, and pump control protection method should be indicated in order to provide the optimal system. If users have special needs, our factory can provide pumps with special materials.

Fixed dry installation

The pump device is on the other side of the pump pit and is fixed on the base together with the water inlet pipe. Thanks to the water jacket cooling system, the pump can be guaranteed to run at full load. Advantages: The continuous impact of the water flow on the puddle does not damage the pump and can withstand accidental flooding. Suitable for municipal construction, sewage sludge discharge from underground pumping station ofoverpass.

Mixer as following

Mixer as following

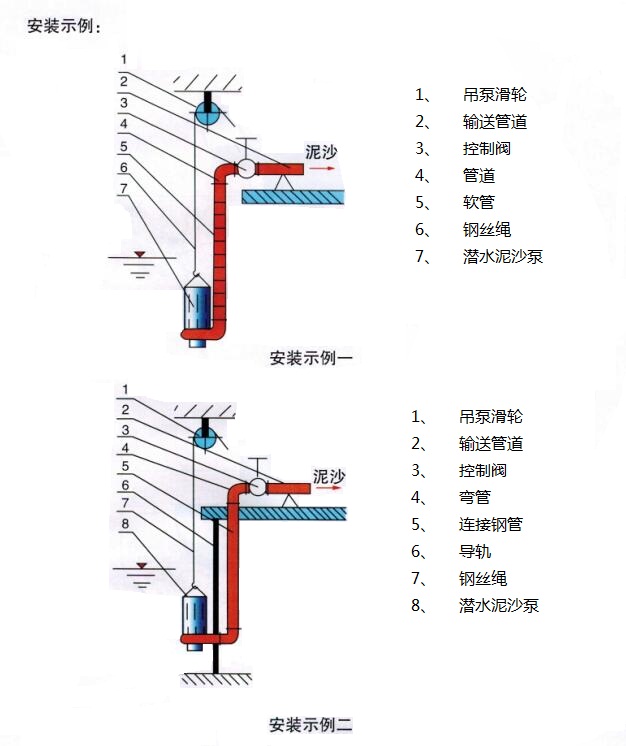

Installation display

Installation display  Application display

Application display

Products photo

Products photo

Notes for use:

Notes for use:

1. Before starting, carefully check whether the electric pump is deformed or damaged during transportation, storage and installation, and whether the fasteners are loose or falling off;

2. Check the cable for damage, breakage and other phenomena. If it is damaged, it must be replaced to avoid leakage;

3. Check whether the power supply is safe and reliable. The rated voltage must match the nameplate.

4. Use a megohmmeter to check the cold state insulation resistance of the stator winding of the motor must not be less than 50MΩ;

5. It is strictly forbidden to use the cable of the pump as the installation and lifting rope to avoid danger;

6. The rotation direction of the pump is counterclockwise when viewed from the water inlet. If it is reversed, any two wires in the cable must be reversed for the connection position, and the pump can rotate forward.

7. The pump should be submerged into the water vertically. It should not be placed horizontally or trapped in sludge. When the pump is transferred, the power must be cut off.

8. Before the electric pump is stopped, it must be put into clean water for several minutes to prevent the sediment from being left in the pump and ensure that the electric pump is clean;

9. When the electric pump is not used for a long time, it should be taken out of the water to reduce the chance of damping the stator winding of the motor and increase the service life of the electric pump;

10. Under normal working conditions, after the electric pump has been working for half a year (it can be advanced to three months if the work intensity is large), maintenance should be performed, worn and worn parts should be replaced, the tightening status should be checked, and bearing grease should be replenished or replaced. And insulating oil in the oil chamber to ensure the good operation of the electric pump;

11. When the water depth exceeds 20 meters, it is recommended that the cables be tied with floats at an interval of 1 meter. When the water pump is running, the cables are broken. When the water is transported over long distances, the water pipes are tied with floats at a distance of 5 meters to facilitate movement.

Failure and solution:

| Failure | Possible reason | Solution |

| High current exceeds rated current | 1.The pump has rub resistance | 1.Adjust the gap |

| 2. The head of the device is too low, and the pump runs at a large flow rate. | 2.The valve controls the flow or replaces the appropriate head pump | |

| 3.Bearing damage | 3.Replace bearings | |

| The motor makes a strange noise during startup2. Check the circuit and connect the disconnection | 1.The voltage is too low | 1.Adjust the voltage to the rated value |

| 2.Single-phase motor operation | 2. Check the circuit and connect the disconnection | |

| 3, foreign matter stuck in the pump | 3.Remove foreign bodies | |

| 4, the impeller and the inner pump cover or suction plate | 4.Adjust the impeller clearance to the normal value | |

| No or little water | 1, impeller reverse | 1.Replace any two-phase power cord |

| 2.The water filter is blocked | 2.Clear the obstruction | |

| 3.The water inlet leaks out of the water | 3. Lower the pump position to submersion | |

| 4. Leakage or blockage of water pipe | 4.Replace water pipes or remove dirt | |

| 5.The actual head is too high | 5.Choose a pump with a suitable head | |

| Insulation resistance drops below 0.5MΩ | 1.The cable connector is damaged | 1.Reprocess the cable connector |

| 2. Stator winding insulation damage | 2.Replace the stator winding | |

| 3.Water in the motor cavity | 3. Exclude moisture and dry windings | |

| 4.The cable is damaged | 4.Repair cables | |

| Unstable running and severe vibration | 1.The impeller is severely worn | 1、replace the impeller |

| 2. Debris stuck on rotating parts | 2、clear the stuck things | |

| 3.Bearing damage | 3、change bearings |

ZNQ, ZNQX,ZNQL, ZNQR, ZNQRX technical data (only for refrence)

|

No. |

Model |

Flow rate M3/h |

Head m |

Diameter mm |

Power kw |

Granularitymm |

|

50ZNQ15-25-3 |

15 |

25 |

50 |

3 |

10 |

|

|

50ZNQ30-15-3 |

30 |

15 |

50 |

15 |

||

|

50ZNQ40-13-3 |

40 |

13 |

50 |

15 |

||

|

80ZNQ50-10-3 |

50 |

10 |

80 |

20 |

||

|

50ZNQ24-20-4 |

24 |

20 |

50 |

4 |

20 |

|

|

50ZNQ40-15-4 |

40 |

15 |

50 |

20 |

||

|

80ZNQ60-13-4 |

60 |

13 |

80 |

20 |

||

|

50ZNQ25-30-5.5 |

25 |

30 |

50 |

5.5 |

18 |

|

|

80ZNQ30-22-5.5 |

30 |

22 |

80 |

20 |

||

|

100ZNQ65-15-5.5 |

65 |

15 |

100 |

25 |

||

|

100ZNQ70-12-5.5 |

70 |

12 |

100 |

25 |

||

|

80ZNQ30-30-7.5 |

30 |

30 |

80 |

7.5 |

25 |

|

|

80ZNQ50-22-7.5 |

50 |

22 |

80 |

25 |

||

|

100ZNQ80-12-7.5 |

80 |

12 |

100 |

30 |

||

|

100ZNQ100-10-7.5 |

100 |

10 |

100 |

30 |

||

|

80ZNQ50-26-11 |

50 |

26 |

80 |

11 |

26 |

|

|

100ZNQ80-22-11 |

80 |

22 |

100 |

30 |

||

|

100ZNQ130-15-11 |

130 |

15 |

100 |

35 |

||

|

100ZNQ50-40-15 |

50 |

40 |

100 |

15 |

30 |

|

|

100ZNQ60-35-15 |

60 |

35 |

100 |

30 |

||

|

100ZNQ100-28-15 |

100 |

28 |

100 |

35 |

||

|

100ZNQ130-20-15 |

130 |

20 |

100 |

37 |

||

|

150ZNQ150-15-15 |

150 |

15 |

150 |

40 |

||

|

150ZNQ200-10-15 |

200 |

10 |

150 |

40 |

||

|

100ZNQ70-40-18.5 |

70 |

40 |

100 |

18.5 |

35 |

|

|

150ZNQ180-15-18.5 |

180 |

15 |

150 |

40 |

||

|

100ZNQ60-50-22 |

60 |

50 |

100 |

22 |

28 |

|

|

100ZNQ100-40-22 |

100 |

40 |

100 |

30 |

||

|

150ZNQ130-30-22 |

130 |

30 |

150 |

32 |

||

|

150ZNQ150-22-22 |

150 |

22 |

150 |

40 |

||

|

150ZNQ200-15-22 |

200 |

15 |

150 |

40 |

||

|

200ZNQ240-10-22 |

240 |

10 |

200 |

42 |

||

|

100ZNQ80-46-30 |

80 |

46 |

100 |

30 |

30 |

|

|

100ZNQ120-38-30 |

120 |

38 |

100 |

35 |

||

|

100ZNQ130-35-30 |

130 |

35 |

100 |

37 |

||

|

150ZNQ240-20-30 |

240 |

20 |

150 |

40 |

||

|

200ZNQ300-15-30 |

300 |

15 |

200 |

50 |

||

|

100ZNQ100-50-37 |

100 |

50 |

100 |

37 |

30 |

|

|

150ZNQ150-40-37 |

150 |

40 |

150 |

40 |

||

|

200ZNQ300-20-37 |

300 |

20 |

200 |

50 |

||

|

200ZNQ400-15-37 |

400 |

15 |

200 |

50 |

||

|

150ZNQ150-45-45 |

150 |

45 |

150 |

45 |

40 |

|

|

150ZNQ200-30-45 |

200 |

30 |

150 |

42 |

||

|

200ZNQ350-20-45 |

350 |

20 |

200 |

50 |

||

|

200ZNQ500-15-45 |

500 |

15 |

200 |

50 |

||

|

150ZNQ150-50-55 |

150 |

50 |

150 |

55 |

40 |

|

|

150ZNQ250-35-55 |

250 |

35 |

150 |

42 |

||

|

200ZNQ300-25-55 |

300 |

25 |

200 |

50 |

||

|

200ZNQ400-20-55 |

400 |

20 |

200 |

|||

|

250ZNQ600-15-55 |

600 |

15 |

250 |

50 |

||

|

100ZNQ140-60-75 |

140 |

60 |

100 |

75 |

40 |

|

|

150ZNQ200-50-75 |

200 |

50 |

150 |

45 |

||

|

150ZNQ240-45-75 |

240 |

45 |

150 |

45 |

||

|

200ZNQ350-35-75 |

350 |

35 |

200 |

50 |

||

|

200ZNQ380-30-75 |

380 |

30 |

200 |

50 |

||

|

200ZNQ400-25-75 |

400 |

25 |

200 |

50 |

||

|

200ZNQ500-20-75 |

500 |

20 |

200 |

50 |

||

|

150ZNQ250-50-90 |

250 |

50 |

150 |

90 |

44 |

|

|

200ZNQ400-40-90 |

400 |

40 |

200 |

50 |

||

|

250ZNQ550-25-90 |

550 |

25 |

200 |

90 |

50 |

|

|

250ZNQ400-50-110 |

400 |

50 |

250 |

110 |

50 |

|

|

300ZNQ600-35-110 |

600 |

35 |

300 |

50 |

||

|

300ZNQ660-30-110 |

660 |

30 |

300 |

50 |

||

|

300ZNQ800-22-110 |

800 |

22 |

300 |

50 |

||

|

250ZNQ500-45-132 |

500 |

45 |

250 |

132 |

50 |

|

|

300ZNQ700-35-132 |

700 |

35 |

300 |

50 |

||

|

300ZNQ800-30-132 |

800 |

30 |

300 |

50 |

||

|

300ZNQ1000-22-132 |

1000 |

22 |

300 |

50 |

Note: This parameter is for reference, please specify when ordering: flow, head, power, caliber and other parameters, subject to contract

Wear-resistant rubber sand pumping pipe

Rubber pipe size

50mm、65mm、80mm、100mm、150mm、200mm、250mm、300mm、350mm、400mm等。

thickness:6mm、8mm、10mm、12mm、14mm、16mm、18mm、20mm等。

Under pressure:2、3、4、6、8、10kg

Both ends of the pipe can be equipped with matching flanges for easy connection.

ZNL type vertical mud pump

Product introduction:

ZNL vertical mud pump is mainly composed of pump casing, impeller, pump base, motor base and motor. The pump casing, impeller and guard plate are made of wear-resistant alloy, which has high strength, wear resistance, good passability and high efficiency. It can be used vertically or obliquely, with a small footprint. The pump casing needs to be buried in the medium to work, and it is easy to start without water introduction. There are various specifications of the switchboard length, so that the user can choose the unit according to the purpose.

Mainly used in environmental protection, municipal engineering, thermal power plants, gas coking plants, oil refineries, steel mills, mining, papermaking, cement plants, food plants, printing and dyeing industries to pump thick liquids, heavy oil, oil residues, and dirty liquid , Sludge, mortar, quicksand, and mobile sludge from urban sewage channels, as well as fluids and corrosive liquids containing sediment.

Model meaning:

100 ZNL(X)100-28-15

100 –Nominal diameter of pump discharge port(mm)

ZNL– vertical mud pump

(X) –stainless steel

100 – rated flow(m3/h)

28 –rated head (m)

15 – motor rated power (Kw)

Products advantage :

1. The pump is sealed with 2 sets of hard alloy mechanical seals;

2. The auxiliary impeller is used to reduce the impeller back pressure and prolong the life of the seal;

3. The over-current parts are made of high-chromium wear-resistant alloy and other materials to resist abrasion;

4. In addition to the main impeller, there is a stirring impeller, which can stir the sediment deposited on the bottom of the water into a turbulent flow and extract it;

5. The stirring impeller is directly close to the deposition surface, with high concentration and high efficiency.

use:

1. Cleaning of chemical plant, steel smelting, ore dressing plant sedimentation tank, power plant sink coal pond, sewage plant oxidation ditch sedimentation pond.

2. Sediment removal, silt, municipal pipelines, and rainwater pumping station construction.

3. Extract all kinds of silicon carbide, quartz sand, steel slag and water slag solid particles.

4. Fly ash, slime and coal slurry transportation in power plant.

5. Tailings transportation, various tailings ore, slurry, ore slurry, coal slurry, slag, slag treatment, etc.

6. Sand making, ore dressing, gold rushing, iron sand extraction and conveyance of slurry materials containing various slags.

7. Transport mediums such as sand, ore slurry, coal slurry, sand and gravel containing larger solid particles.

8. If it cooperates with a high-pressure water pump to form a hydraulic mechanized engineering unit, it can be used for dredging works in urban rivers, coastal areas, ports, lakes, reservoirs, and so on

Physical map and structure of vertical mud pump

Pump assembly

Pump assembly

User assembly :

User assembly :

Model ZNL、ZNLX(only for reference)

Model ZNL、ZNLX(only for reference)

|

No. |

Model |

Flow rate M3/h |

Head m |

Diameter mm |

power kw |

Granularitymm |

|

1 |

50ZNL15-25-3 |

15 |

25 |

50 |

3 |

10 |

|

2 |

50ZNL30-15-3 |

30 |

15 |

50 |

15 |

|

|

3 |

50ZNL40-13-3 |

40 |

13 |

50 |

15 |

|

|

4 |

80ZNL50-10-3 |

50 |

10 |

80 |

20 |

|

|

5 |

50ZNL24-20-4 |

24 |

20 |

50 |

4 |

20 |

|

6 |

50ZNL40-15-4 |

40 |

15 |

50 |

20 |

|

|

7 |

80ZNL60-13-4 |

60 |

13 |

80 |

20 |

|

|

8 |

50ZNL25-30-5.5 |

25 |

30 |

50 |

5.5 |

18 |

|

9 |

80ZNL30-22-5.5 |

30 |

22 |

80 |

20 |

|

|

10 |

100ZNL65-15-5.5 |

65 |

15 |

100 |

25 |

|

|

11 |

100ZNL70-12-5.5 |

70 |

12 |

100 |

25 |

|

|

12 |

80ZNL30-30-7.5 |

30 |

30 |

80 |

7.5 |

25 |

|

13 |

80ZNL50-22-7.5 |

50 |

22 |

80 |

25 |

|

|

14 |

100ZNL80-12-7.5 |

80 |

12 |

100 |

30 |

|

|

15 |

100ZNL100-10-7.5 |

100 |

10 |

100 |

30 |

|

|

16 |

80ZNL50-26-11 |

50 |

26 |

80 |

11 |

26 |

|

17 |

100ZNL80-22-11 |

80 |

22 |

100 |

30 |

|

|

18 |

100ZNL130-15-11 |

130 |

15 |

100 |

35 |

|

|

19 |

100ZNL50-40-15 |

50 |

40 |

100 |

15 |

30 |

|

20 |

100ZNL60-35-15 |

60 |

35 |

100 |

30 |

|

|

21 |

100ZNL100-28-15 |

100 |

28 |

100 |

35 |

|

|

22 |

100ZNL130-20-15 |

130 |

20 |

100 |

37 |

|

|

23 |

150ZNL150-15-15 |

150 |

15 |

150 |

40 |

|

|

24 |

150ZNL200-10-15 |

200 |

10 |

150 |

40 |

|

|

25 |

100ZNL70-40-18.5 |

70 |

40 |

100 |

18.5 |

35 |

|

26 |

150ZNL180-15-18.5 |

180 |

15 |

150 |

40 |

|

|

27 |

100ZNL60-50-22 |

60 |

50 |

100 |

22 |

28 |

|

28 |

100ZNL100-40-22 |

100 |

40 |

100 |

30 |

|

|

29 |

150ZNL130-30-22 |

130 |

30 |

150 |

32 |

|

|

30 |

150ZNL150-22-22 |

150 |

22 |

150 |

40 |

|

|

31 |

150ZNL200-15-22 |

200 |

15 |

150 |

40 |

|

|

32 |

200ZNL240-10-22 |

240 |

10 |

200 |

42 |

|

|

33 |

100ZNL80-46-30 |

80 |

46 |

100 |

30 |

30 |

|

34 |

100ZNL120-38-30 |

120 |

38 |

100 |

35 |

|

|

35 |

100ZNL130-35-30 |

130 |

35 |

100 |

37 |

|

|

36 |

150ZNL240-20-30 |

240 |

20 |

150 |

40 |

|

|

37 |

200ZNL300-15-30 |

300 |

15 |

200 |

50 |

|

|

38 |

100ZNL100-50-37 |

100 |

50 |

100 |

37 |

30 |

|

39 |

150ZNL150-40-37 |

150 |

40 |

150 |

40 |

|

|

40 |

200ZNL300-20-37 |

300 |

20 |

200 |

50 |

|

|

41 |

200ZNL400-15-37 |

400 |

15 |

200 |

50 |

|

|

42 |

150ZNL150-45-45 |

150 |

45 |

150 |

45 |

40 |

|

43 |

150ZNL200-30-45 |

200 |

30 |

150 |

42 |

|

|

44 |

200ZNL350-20-45 |

350 |

20 |

200 |

50 |

|

|

45 |

200ZNL500-15-45 |

500 |

15 |

200 |

50 |

|

|

46 |

150ZNL150-50-55 |

150 |

50 |

150 |

55 |

40 |

|

47 |

150ZNL250-35-55 |

250 |

35 |

150 |

42 |

|

|

48 |

200ZNL300-24-55 |

300 |

24 |

200 |

50 |

|

|

49 |

250ZNL600-15-55 |

600 |

15 |

250 |

50 |

|

|

50 |

100ZNL140-60-75 |

140 |

60 |

100 |

75 |

40 |

|

51 |

150ZNL200-50-75 |

200 |

50 |

150 |

45 |

|

|

52 |

150ZNL240-45-75 |

240 |

45 |

150 |

45 |

|

|

53 |

200ZNL350-35-75 |

350 |

35 |

200 |

50 |

|

|

54 |

200ZNL380-30-75 |

380 |

30 |

200 |

50 |

|

|

55 |

200ZNL400-25-75 |

400 |

25 |

200 |

50 |

|

|

56 |

200ZNL500-20-75 |

500 |

20 |

200 |

50 |

|

|

57 |

250ZNL400-50-110 |

400 |

50 |

250 |

110 |

50 |

|

58 |

300ZNL600-35-110 |

600 |

35 |

300 |

50 |

|

|

59 |

300ZNL660-30-110 |

660 |

30 |

300 |

50 |

|

|

60 |

300ZNL800-22-110 |

800 |

22 |

300 |

50 |

|

|

61 |

250ZNL500-45-132 |

500 |

45 |

250 |

132 |

50 |

|

62 |

300ZNL700-35-132 |

700 |

35 |

300 |

50 |

|

|

63 |

300ZNL800-30-132 |

800 |

30 |

300 |

50 |

It is recommended to buy a national standard motor, and a non-national standard motor is recommended to purchase a larger model motor. Internal structure: It is for reference only, and the actual product shall prevail. If there is any part of the structure optimized and upgraded, without notice.

Quality and after sales

1. Quality and technical standards: Manufactured according to the national standard CJ / T3038-1995, and the quality assurance system is implemented according to ISO9001.

2. Technical Standards, Conditions and Duration of Supplier’s Responsibility for Quality: Three Guarantees for Quality Except Vulnerable Parts.

3. During the warranty period; under the condition that the conveying medium meets the requirements of the pump’s overcurrent parts and can comply with the instruction manual, when the product is damaged due to poor manufacturing or cannot work normally, the factory will replace or repair it for free, and the wearing parts are not here the term.

Fourth, the factory ensures low-cost long-term supply of accessories for customers.

Fifth, for the cooperation unit, the factory completely provides after-sales service to customers.

Six, special conditions, please specify when ordering, so as not to affect after-sales.

Order notice :

1. Please indicate the product specifications and ordering range when ordering;

2. Impellers, stirring impellers, upper and lower guard plates, mechanical seals and other wearing parts can be purchased separately for emergency use according to needs;

3. If the user’s application does not meet the conditions of use, such as voltage, frequency, or water quality, the user can ask for special orders.