QSY Reamer hydraulic mud pump

product description:

QSY series reamer hydraulic mud pump is a new mud pump installed on the arm of the excavator and driven by the hydraulic system of the excavator. It is divided into 12-inch, 10-inch, 8-inch, 6-inch and 4-inch series according to the outlet diameter. Various specifications. It is mainly used as an auxiliary device of the excavator. When there is much water, silt, sediment, and sand are not conducive to excavation, and it is not convenient for on-board transportation, the hydraulic sediment pump is used for extraction, which greatly improves the work efficiency. Widely used in inland waterway dredging projects, port sediment management, sediment extraction from tailings ponds, beneficiation, municipal sewer drainage, etc.

Model meaning :

200QSY500-20

200–Nominal diameter of pump discharge port (mm)

QSY–hydraulic mud pump

500–rated flow rate (m3/h)

20 –rated head of delivery (m)

Pump selection:

1. According to the actual working conditions of the user, determine the required lift, flow, and transportation distance;

2. Check the parameters of the excavator to find out the parameters such as the displacement and pressure of the hydraulic system of the excavator;

3. Select the hydraulic motor model from this;

4. Calculate the actual output power of the hydraulic system of the excavator and choose a suitable pump.

Working principle

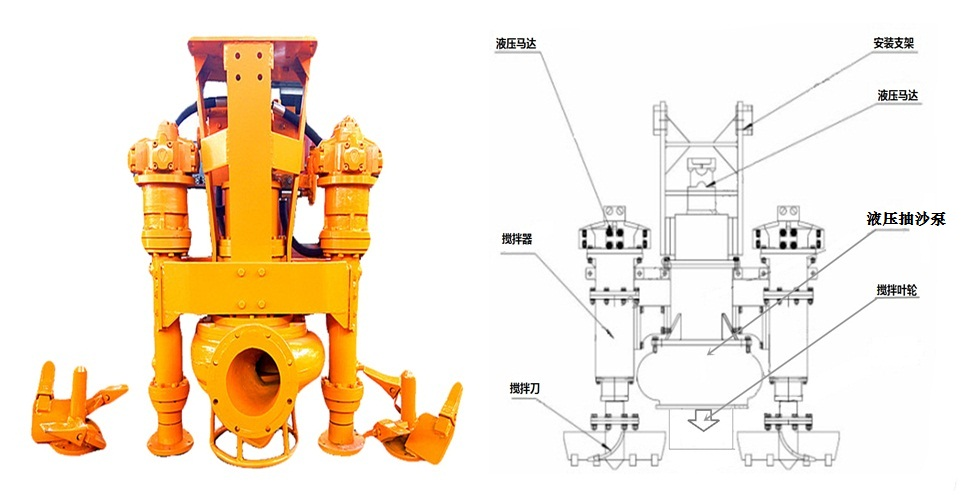

QSY reamer hydraulic sand pump is a new type of sand pump that is powered by a hydraulic system, with a motor as the actuator, which converts hydraulic energy into mechanical energy. When working, the rotation of the impeller through the water pump transfers energy to the slurry medium, causing it to generate a certain flow rate, driving the solids to flow, and realizing the transfer of the slurry.

The hydraulic motor is selected from domestic famous quantitative plunger motor and five-star motor, which has the characteristics of advanced and reasonable structure, good performance, high efficiency and stable work. According to the actual working conditions of customers, different displacement motors are selected.

Working conditions:

1.Excavator hydraulic drive, this pump is suitable for Carter, Volvo, Komatsu, Hitachi, Sumitomo, Kobelco, Doosan, Hyundai, XCMG, Sany, Yuchai, Liugong, Longgong, Zhonglian, Shanzhong, Lin Excavators of various series such as 120, 150, 200, 220, 240, 300, 330, 360, 400, etc.

2. Driven by hydraulic pump station. The hydraulic motor used in this pump is suitable for small, medium and large series hydraulic pump stations.

Product outline structure

Main features

1.The bottom of the pump is equipped with a stirring impeller, and can be equipped with a reamer or a cage on both sides to loosen the deposits, increase the extraction concentration, and realize automatic retraction. Mix thoroughly for easier handling.

2. This pump can handle solid materials with a maximum particle size of 50mm, and the solid-liquid extraction concentration can reach more than 70%;

Note: Due to the different working conditions, the output of the pump may also vary depending on the factors such as the media being processed, on-site operation, and delivery distance.

3. This device is mainly installed on the excavator. The power is provided by the hydraulic station of the excavator, which can realize free transfer, and the power source is a diesel engine. It can solve the problem of inconvenience of electricity during construction in remote areas.

4. Flowing parts: The pump casing, impeller, guard plate, and stirring impeller are all made of high-chromium alloy, and other materials can be customized.

5. Adopt unique sealing device to avoid frequent replacement of machine seals and improve Product advantages: Compared with electric submersible sand pumps, it has the following advantages:

1.Hydraulic transmission has small motion inertia and fast response speed, which can realize stepless speed regulation in a wide range;

2. Overload protection can be realized automatically, there is no burning motor phenomenon;

3. The concentration of solids such as mortar, sediment and slag is high, which can reach more than 70%;

4. Connected to a machine with a hydraulic system such as an excavator, it can realize free transfer, especially in remote areas, when the power is insufficient, the advantages are more obvious;

5. It can be used as an attachment of the excavator, and it can be extracted and transported long distances when it is unfavorable to increase the value of the excavator.

The main purpose:

1. Sand extraction, dredging, dredging, and removal of sediments from ports, rivers, and lakes.

2. Sediment drainage, mud, and drainage during the construction of the project, drainage of sediment, extraction of sediment, crushed stones, etc., and construction of a seaport.

3. Iron ore, tailings pond, ore dressing plant and other mines discharge slag, discharge slurry and all solutions containing solid matter.

4. It is used in metallurgy, iron and steel and other industries to extract high-concentration tailings, waste slags and high-temperature iron slags and iron chips.

5. Emergency drainage and clearing of mud after the disaster.

6. It can be applied to shallow water areas and marshlands, and can be used for water conservancy projects such as river dredging, lake development, wetland park construction, coastal beach development, salt lake development, tailings mine management, and marshland development projects.

Compared with mechanical transmission and electrical transmission, hydraulic transmission has the following advantages:

| Easy to achieve stepless speed regulation. | Easy to automate. |

| Passing dynamic balance. | Easy to implement overload protection. |

| Large carrying capacity. | Easy to achieve standardization, serialization and generalization. |

| Long component life. | Small size, light weight and compact structure. |

Installation steps

1. First make sure that the excavator has been installed with hydraulic lines to ensure that the lines are unobstructed.

2. Remove the bucket and connect the hydraulic sand pump to the excavator arm through the mounting plate.

3. Connect the oil inlet pipe, oil return pipe, and oil spill pipe. Note: The oil pipes must be connected correctly.

4. Install the reamer head, taking care not to reverse it.

5. Test machine, if the reamer head is reversed, just reverse the two reamer.

Notes for use:

1. Ensure that the hydraulic oil in the system is pure and has few impurities, and has good lubricity, compatibility and stability;

2. According to the existing hydraulic system pressure, displacement, efficiency, etc., reasonably equip the sediment pump so that the system can operate normally and must not exceed the system load for a long time;

3. When used in conjunction with an excavator, the excavator arm should move lightly and slowly. It is strictly forbidden to slam or smash it under hard working conditions to avoid damaging the pump body

4. Use standard specification hydraulic oil pipes, use specified bolts and tighten them with specified torque, unqualified installation will cause failure, damage or oil leakage;

5. When the equipment is transferred, the hydraulic oil port should be kept clean to prevent entry of impurities, etc., which will affect the normal service life of the motor;

6. It is forbidden to modify or disassemble the equipment without permission, otherwise it will cause abnormal operation or abnormal operation.

QSY main technical data (only for reference )

|

No. |

Technical data |

|||||

|

Model |

Outlet diametermm |

Flow rate m³/h |

head m |

Electric motor pump power kw |

Graininess mm |

|

|

100QSY100-10 |

100 |

100 |

10 |

7.5 |

25 |

|

|

80QSY50-22 |

80 |

50 |

22 |

7.5 |

20 |

|

|

80QSY50-26 |

80 |

50 |

26 |

11 |

20 |

|

|

100QSY80-22 |

100 |

80 |

22 |

11 |

25 |

|

|

100QSY130-15 |

100 |

130 |

15 |

11 |

25 |

|

|

100 QSY 60-35 |

100 |

60 |

35 |

15 |

25 |

|

|

100 QSY 100-28 |

100 |

100 |

28 |

15 |

25 |

|

|

150QSY 150-15 |

150 |

150 |

15 |

15 |

30 |

|

|

100QSY100-35 |

100 |

100 |

35 |

22 |

25 |

|

|

100QSY130-30 |

100 |

130 |

30 |

22 |

25 |

|

|

150QSY150-22 |

150 |

150 |

22 |

22 |

30 |

|

|

150QSY200-15 |

150 |

200 |

15 |

22 |

35 |

|

|

150QSY240-10 |

150 |

240 |

10 |

22 |

35 |

|

|

100QSY150-35 |

100 |

150 |

35 |

30 |

25 |

|

|

150QSY180-30 |

150 |

180 |

30 |

30 |

30 |

|

|

150QSY240-20 |

150 |

240 |

20 |

30 |

35 |

|

|

200QSY300-15 |

200 |

300 |

15 |

30 |

35 |

|

|

150QSY280-20 |

200 |

280 |

20 |

37 |

35 |

|

|

200QSY350-15 |

200 |

350 |

15 |

37 |

35 |

|

|

150QSY200-30 |

150 |

200 |

30 |

45 |

30 |

|

|

200QSY350-20 |

200 |

350 |

20 |

45 |

40 |

|

|

200QSY400-15 |

200 |

400 |

15 |

45 |

40 |

|

|

150QSY240-35 |

150 |

240 |

35 |

55 |

30 |

|

|

200QSY300-24 |

200 |

300 |

24 |

55 |

40 |

|

|

200QSY500-15 |

200 |

500 |

15 |

55 |

45 |

|

|

150QSY240-45 |

150 |

240 |

45 |

75 |

35 |

|

|

200QSY350-35 |

200 |

350 |

35 |

75 |

45 |

|

|

200QSY400-25 |

200 |

400 |

25 |

75 |

45 |

|

|

200QSY500-20 |

200 |

500 |

20 |

75 |

46 |

|

|

200QSY400-40 |

200 |

400 |

40 |

90 |

45 |

|

|

250QSY550-25 |

200 |

550 |

25 |

90 |

45 |

|

|

300QSY660-30 |

300 |

660 |

30 |

110 |

50 |

|

|

300QSY800-22 |

300 |

800 |

22 |

110 |

50 |

|

|

250QSY500-45 |

300 |

500 |

45 |

132 |

50 |

|

|

300QSY700-35 |

300 |

700 |

35 |

132 |

50 |

|

|

300QSY1000-22 |

300 |

1000 |

22 |

132 |

50 |

|

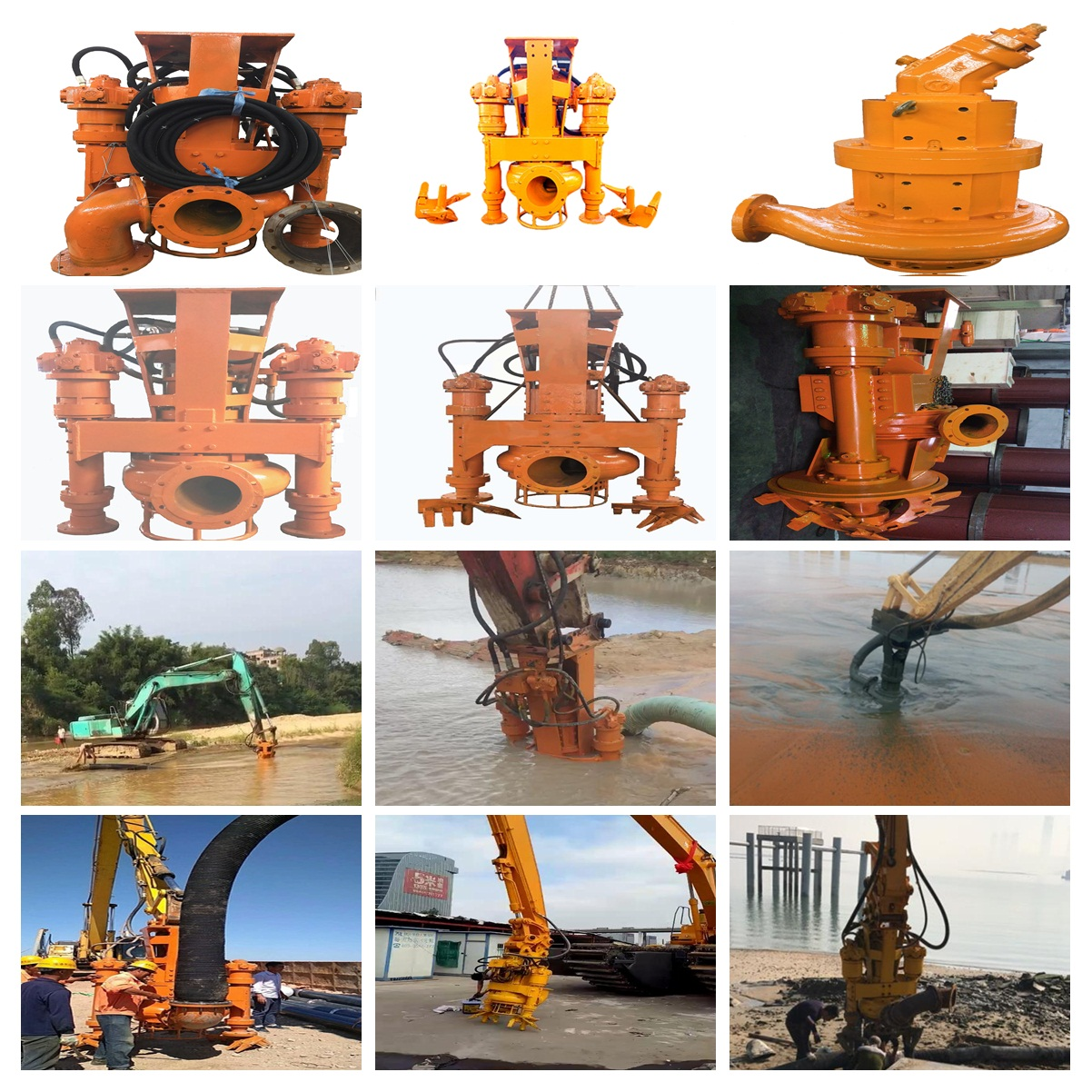

Products photo and working site :